As I have started scanning CD matrix numbers, I’ve found that some discs (particularly older ones) are very difficult to scan - the codes are much fainter than on other discs, and only visible to the eye when I hold it to the light at a particular angle. Anyone found any tricks for scanning those?

That’s great!

No, I don’t have any special trick either, except maybe adjusting the brightness and contrast of the image.

I haven’t had any that I can’t read at all. And for “microscopic” SID codes I also have my microscope.

A cheap USB microscope is an absolute must.

Random example that I own: https://www.amazon.co.uk/gp/product/B07DRGR6LX/

Well that might be fun but…my interest/willingness for this endeavor falls in between the levels of “do an extra scan” and “buy more gear”.

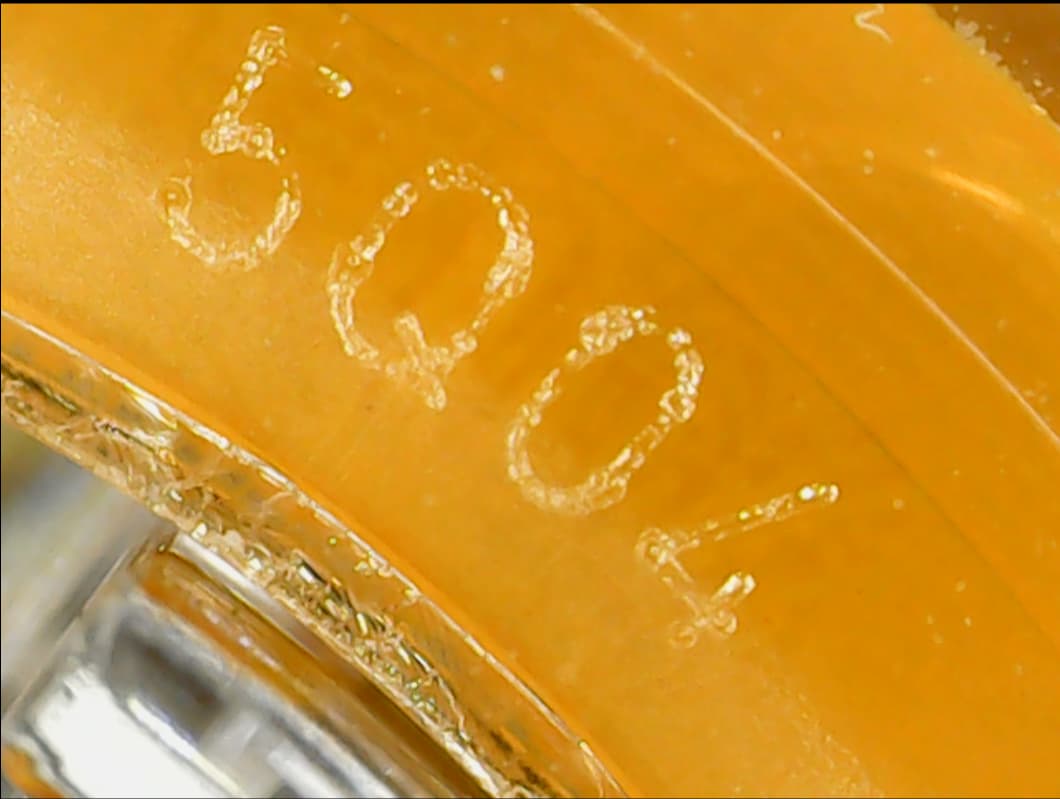

A scanner can’t get to this level of detail. Even at 1200dpi it is hard to read. It is also quicker to use the microscope than a scanner.

As to fun - this thing is great on things like moss or fossils. It is a great little toy way beyond reading CDs.

These mould SID codes in particular are often invisible on scans. But it is also possible to see them with a good magnifying glass.

I’m using the “replace color” option in Photoshop for the matrix runout to make it stand out more (works for most CDs) and the super-makro mode of my smartphone (p30 pro) for the mould code. Helps a lot.

But the microscope idea is great too.

I recently bought this one based on your suggestion and it’s done a great job of reading tiny codes. It also works great for plants, bugs, and other little things.

I had to resort to using my Nikon DSLR with to 105mm macro lens… primarily due to the necessity of controlling the shape, direction, area, angle, etc. of the light source. Back in the 1980’s and 1990’s various CD manufacturing plants, used various different methods of engraving a matrix code on a particular production run of a CD.

So, some of them possibly used a YAG laser to cut the letters and numbers as a few dozen dots, or parallel lines… or literally just drawn out the edges of the letters and numbers as vectors.

Some of them look like someone carefully scratched the letters and numbers into the surface of the stamper by hand, with a sharp metal object.

Anyway, depending on the microscopic shape, of the area, of the characters, the angle of the light is most important, so plan on moving your light(s) and camera around every time for every disc. Also get used to constantly adjusting the aperture of your lens too… because you’re basically taking a photo in the mirror, and with a large depth of field you’re going to just get a picture of your light source.

(Also, you’ll need to keep decreasing your shutter speed, and cranking down your ISO, so you’re not constantly blinding yourself by taking a photo of your light source in a mirror…) (but only sometime when the reflection angle is small… many times the angle between the light and the lens is large… and you’ll need to increase your shutter speed, because now it’s dark…)

So… what works pretty well, maybe 70% of the time, is a diffuse light box surrounding as much of your CD as possible. You can improvise with any large white or gray surface (paper or cloth, etc.) that’s evenly lit. Keep in mind that you will see the shape of the light in the reflection on the CD. If you put a bright or dark object nearby, you’ll see a bright or dark stripe on the CD…

So… this doesn’t work for some matrix code engravings… so in those cases I use a white LED flashlight (point source), and with the camera on a tripod (same as above if I didn’t mention) move the camera, CD, and flashlight around until the matrix is clearly visible. I have a remote control shutter release for my camera, with makes it so much easier to do…

I’ve experimented with a green laser pointer too, sometime that works better, and other times worse. It is really good if you want to get a clear photo of which areas of the CD have engraved data, and which areas have been left unwritten. (In a light box, the surface of the CD will appear a smooth continuous gray color – with a laser pointer you get a bright stripe on a dark background, but within the stripe you can clearly see a high contrast “grain” where the lands and pits are engraved)

So… on some CDs, none of the above work, because you need the light reflected almost exactly perpendicular to the surface of the CD. For those CDs I need to use a ring flash. (It works for other CDs too, but mine was built back in 1972, and is a pain to use, and I can’t see what I’m doing, and the capacitors take like 15 seconds to recharge after each flash…) The reflection angle is so narrow, the lens is physically in the way of the light. You can tilt the camera or CD a little bit to make this easier, but you will introduce distortion and blurring…

… unless you have a bellows or tilt-shift lens.

I forgot to mention: I mount my camera on a tripod, and set it level to the surface on which I’m placing the CD, so that all parts of the CD are exactly the same distance from the camera lens. (i.e. the image is flat) I open the aperture as wide as possible, so only the surface of the CD is in focus, and the reflected light source is out of focus. (I even use a bubble level to check.)

… And then my life gets complicated and I don’t upload the photos for a year…

I think @foxgrrl just summed up perfectly why I don’t take photos of SIDs.  Just go for the strong light to spot it, and a microscope to read it. And even then I’ll cross check with other data to check what I read makes sense. The classic example being misreading IFPI L046 as L045 due to the fonts.

Just go for the strong light to spot it, and a microscope to read it. And even then I’ll cross check with other data to check what I read makes sense. The classic example being misreading IFPI L046 as L045 due to the fonts.

For mastering SIDs, I had the best results with high-resolution scans (I use 1200dpi, but 600dpi should be fine, even for the tiny ones)

Mould SIDs are more tricky, but i found a good way to do it too:

I locate it with the help of a magnifying glass, and then I take a “photograph” with the microscope (lighting can be varied until it is visible).

Of course, a few problems remain. Mastering SIDs may be hidden under a bulging ring or may have been distorted during duplication. If written in an area that is not metal plated on the finished disc, the mastering SID may be invisible, or partially invisible, which can lead to misinterpretations, as @IvanDobsky mentioned.

I had to google what “matrix code” was being talked about, would love a Discourse on-hover explanation. Turns out that I’ve accidentally scanned a few without really paying attention to the data inside. I certainly would have paid more attention had I known.

I gave up on that. Even 1200dpi was too hit and miss depending on lighting. That’s why I bought the microscope. I always scan 600dpi - and here is a rare time I caught all the SIDS:

Even this example it is hard to read. I think it is fine to have a photo of the main Matrix on MB and not worry too much about the SID photos. They change too often in a release, but the main Matrix sticks to a pattern for that pressing. This seems more useful for identification. Otherwise we’ll potentially end up with dozens of extra images of SIDs from various angles on a release. Just write SIDs up in the Release annotation.

@Avamander - watch out, these geeky details get far too addictive. ![]()

![]() You’ll end up knowing far too much about the ownership of your local pressing plants over the decades.

You’ll end up knowing far too much about the ownership of your local pressing plants over the decades. ![]()

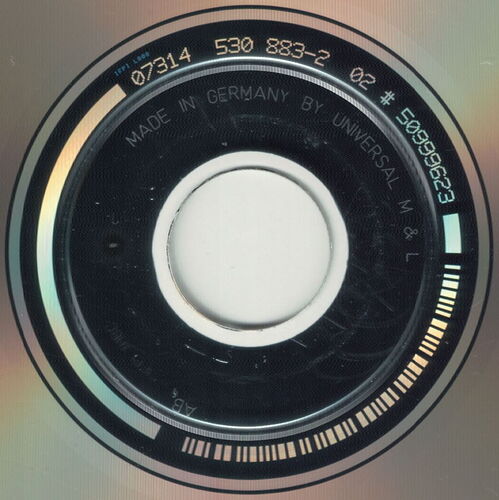

A simplified short crash course using the above image:

Matrix: 07314 530 883-2 02 # 50999652

Inner Matrix: MADE IN GERMANY BY UNIVERSAL M&L AB

Mastering SID: IFPI L008 (At 11 o’clock on the image)

Mould SID: IFPI 01BC (At 8 o’clock on the image)

Matrix is generally a Catalogue number, and sometimes the n’th glass master. Varies between manufacturer. ( Cat No here is 530 883-2, barcode 731453088320 )

Inner Matrix sometimes appears and mentions the actual factory that pressed the CD. In this case the AB is also likely telling you this is an n’th variation of this glass master.

Other times the factory is in the main matrix text.

Mastering SID: This is the machine the Glass Master was made on. See above @foxgrrl PDF and @HibiscusKazeneko’s link up the page. This should be unique to a manufacturer, but machines can get moved when companies change hands

Mould SID: this is a reference to the machine the CD was actually pressed on.

I may have some of the above language wrong, but basically that’s how I understand it.

Mastering SIDs are not always where a CD is then pressed. For example: it is common to find UDEN Mastering SIDs on CDs pressed in South Africa. In those cases the Mould SID would change to an SA machine.

Best details to be found on decoding these tends to be at Discogs, but some of us are bringing that knowledge over to the manufacturing Labels and Places here at MB.

With discs from Langenhagen it is often not necessary to use the microscope. … and 1200dpi is probably better. In this picture you have to guess L008.

I recently had a curious example: https://www.discogs.com/release/6288649-Röyksopp-The-Inevitable-End/image/SW1hZ2U6NzQ2NTA5MzY=

It looks like an attempt was made to remove the mould SID. IFPI 04** belongs to a plant that closed years ago. (Blackburn)

Up until 2 years ago I had no idea either. ![]()

I agree that 1200dpi is better, but even that is not enough sometimes. So I stopped trying to do it that way and just aim at getting the matrix in the photo and manually read the SIDs with the 'scope.

Is that printed on two different layers? Or just double printed? The Blackburn kit may have been sold \ moved to Telford? For some reason I think I have seen something or other Sound Performance and moving presses around. I know they press in more than one plant.

Here’s something similar I had this weekend. A 2009 genuine Blackburn example pressed in Blackburn (IFPI L135): https://www.discogs.com/release/1661204-The-Prodigy-Invaders-Must-Die

On my copy of this I just couldn’t find a mould SID at all. It also had that same telephone number and Stacked company logo on it as your CD and IFPI LP76. https://www.discogs.com/release/6625234-The-Prodigy-Invaders-Must-Die

My guess - they are using kit that came from the old plant and forgot to change the numbers.

So maybe they took Blackburn masters on to the LP76 pressing plant and sometimes forgot to wipe the old mould codes off?

(@Avamander - this is a warning of the kind of mad rabbits holes you end up running down when looking at SIDs… ![]()

![]() )

)

Only one at the surface. The second is a reflection from the metal layer (only one). And it’s really faint - no chance to spot it without microscope.

I don’t think this disc was pressed in Telford. They would have used their own mould SID, but there is none on it (except this faint remnant). I suspected it to have been pressed in Tilburg (they obviously dropped out of IFPI, because discs glassmastered there later also had no more mastering SID codes - although unchanged matrix design). Or it was pressed at any other duplication plant. Without valid IFPI code we will never know… ![]()

They probably tried to remove it. The disc is in top condition, but there is one heavily scratched area and that’s where I found the code.

The telephone number is a funny feature. I wonder if they got a lot of calls that way. ![]()

Telford has made many glass masters for other plants. Variant 2 was probably pressed in Blackburn. Variant 1 is possibly a repress from another plant. (not necessarily a repress, but very likely)

I was also looking at the difference in the Sound Performance logos. No idea the age of my CD as it was second hand. Logo looks more like your 2014 CD. Any idea where IFPI LP76 is? The page for that CD at discogs was added 7 years ago, so could easily be someone bought new in 2015 fitting neatly to a 2014 repress.

I wasn’t thinking of a Telford pressing. More that they took some Blackburn hardware a couple of hours down the road to Telford. And was using that to make up the Masters? Or they had an old Blackburn mould they were using which still had Blackburn numbers scratched into it? It was then shipped off to place unknown to press.

Making their own pirates… sailing from pressing plant to pressing plant knocking out copies…

AFAIK it was one of the last LBRs of Telford. The other was LT23. I’ve done no statistics on Telford, but I suspect the vast majority of LP76 release to have mould SID 73**. And Telford used IFPI codes until the end. You’ll notice, that there are no more releases with IFPI LP76 or IFPI 73** after 2014.

I don’t know what happened to the Blackburn equipment. Maybe it was auctioned. At least parts went to a plant without mould SIDs. (my disc)

![]() it’s not necessarily piracy. IFPI is an optional quality management tool. It was only mandatory when the record companies insisted, but nowadays it’s less interesting. If you don’t need it, you don’t have to use it.

it’s not necessarily piracy. IFPI is an optional quality management tool. It was only mandatory when the record companies insisted, but nowadays it’s less interesting. If you don’t need it, you don’t have to use it.

EDIT: Did you look at the matrix image of your example - looks awful, and that’s not from usage - not a high quality pressing!

EDIT2: I’ve done some ad hoc statistics on LP76/73**: LP76 wrote glassmasters for four to five hundred releases a year, but they pressed less than half of them. (e.g. for the year 2009: 454 releases have discs with LP76, 150 releases also have 73**, 192 releases where pressed with mould SID 73** overall … according to Discogs submissions with a unknown uncertainty).

I don’t know much about that plant. Majority of my CDs are 1990s era.

Yeah, I almost posted it as it is so funky. Looks like a modern art spiders web.

My personal copy of that one is here: https://coverartarchive.org/release/6a75994d-3286-44e2-b6f7-bc89cf507858/32086084320.jpg Less funky scratches, but still no Mould SID.